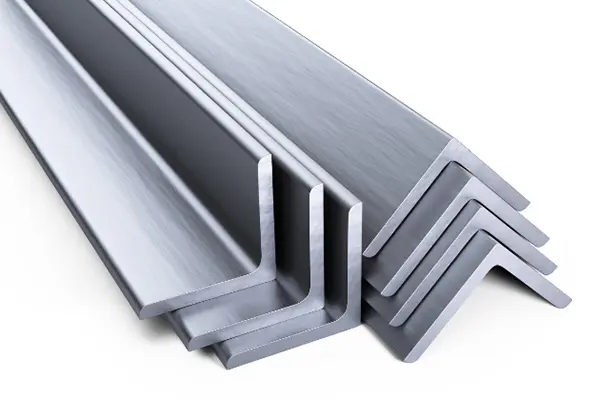

Angle iron, also known as an L-bracket or angle bracket, is a versatile piece of structural metal that has applications across various industries and home projects. Recognized for its L-shaped cross-section, with two legs that join at a right angle, angle iron is available in different lengths, sizes, and materials to suit specific uses. In this article, we’ll explore what angle iron is, its primary uses, and why it’s so valuable in construction, manufacturing, and DIY projects.

Understanding Angle Iron

Angle iron is typically made of steel, though it can also be found in aluminum or galvanized steel. The most common steel varieties are hot-rolled or cold-rolled, each offering different levels of strength, flexibility, and corrosion resistance. Hot-rolled steel is more common in heavy-duty applications due to its durability, while cold-rolled steel is often used where a smooth finish is required. Aluminum angle iron, on the other hand, is lightweight and resistant to rust, making it a great choice for outdoor use or projects that need a lighter structural material.

The key feature of angle iron is its L-shape, with the two legs of the angle forming a 90-degree corner. This design gives angle iron significant strength and load-bearing capacity, making it ideal for reinforcing structures or supporting weight in a way that flat or round metal simply cannot.

Uses of Angle Iron in Construction

In construction, angle iron is commonly used for its strength and durability. It can reinforce the structural integrity of buildings and other structures without adding excessive weight. Here are some specific ways angle iron is used in construction:

- Structural Framing: Angle iron is used to frame and support floors, walls, and ceilings, especially in metal-framed buildings. Its shape allows it to distribute weight effectively, helping to stabilize the entire structure and provide extra support for larger loads.

- Support Beams: In both commercial and residential construction, angle iron is often used as a support beam or lintel. It provides the necessary support for doorways, windows, and other openings, helping to prevent sagging or structural failure over time.

- Bracing and Reinforcement: Angle iron is commonly used to reinforce beams and other structural elements, providing stability against movement and shifting. This is especially important in areas prone to high winds or seismic activity, where added stability is crucial for safety.

- Handrails and Guardrails: Angle iron is frequently used to construct handrails, guardrails, and safety barriers due to its strength and ability to withstand external forces. When installed in staircases or along walkways, angle iron creates a sturdy support that enhances safety.

Applications in Manufacturing and Industry

Angle iron is also widely used in manufacturing and industrial applications due to its ability to support heavy equipment and machinery.

- Equipment Framing and Supports: Industrial machinery requires sturdy frames and supports, and angle iron is a popular choice for these components. Its L-shape makes it highly effective at supporting weight and withstanding vibrations or heavy loads.

- Shelving and Racks: Angle iron is frequently used in the construction of heavy-duty shelving and storage racks, often seen in warehouses or storage facilities. The strength of the angle iron allows it to bear significant weight, making it ideal for storing heavy equipment or materials.

- Transportation and Vehicle Applications: Angle iron is often used in truck beds, trailers, and other vehicle frames that require added durability and load-bearing capability. For example, angle iron can be used to reinforce truck frames, increasing their capacity to handle heavy loads.

Angle Iron in DIY and Home Projects

Angle iron isn’t just limited to large-scale industrial and construction projects; it’s also widely used by DIY enthusiasts and in home projects. Here are a few common home uses for angle irons:

- Furniture Building: Angle iron is often used in the creation of custom furniture, such as tables, chairs, and shelves. Its strength and stability make it an excellent choice for supporting furniture, and its sleek design fits well with modern, industrial aesthetics.

- Garage Storage: Angle iron can help create durable shelving or racks for garages or workshops, where heavier tools and equipment need secure storage. With angle iron, DIYers can build strong, custom shelving to fit unique spaces.

- Framing and Repair: Angle iron can reinforce weak structures, such as wooden fences or damaged frameworks. It can also be used to create custom frames for outdoor fixtures like garden beds, adding durability and weather resistance.

- Outdoor Projects: Angle iron’s resistance to rust (especially when made from galvanized or aluminum steel) makes it suitable for outdoor projects. From plant stands to deck supports, angle iron is a go-to material for projects exposed to the elements.

Benefits of Using Angle Iron

Angle iron offers a combination of affordability, versatility, and strength that is hard to match with other materials. Its L-shaped design allows it to distribute weight evenly and resist bending, which is key in both structural and load-bearing applications. Here are a few key benefits:

- High Load-Bearing Capacity: Angle iron’s shape gives it the ability to support considerable weight, making it ideal for structural reinforcement.

- Durability: Steel angle iron, especially galvanized versions, is corrosion-resistant and suitable for both indoor and outdoor applications.

- Easy to Work With Angle iron can be cut, welded, and drilled, making it easy to modify for custom projects or repair purposes.

Conclusion

Angle iron is a versatile and durable component in construction, industrial settings, and even home DIY projects. Whether it’s providing structural support in a building, reinforcing equipment in manufacturing, or supporting custom furniture at home, angle iron’s unique shape and strength make it an indispensable material. Its affordability and ease of customization add to its appeal, making angle iron a reliable choice for a wide range of practical applications.

Post time: Nov-08-2024