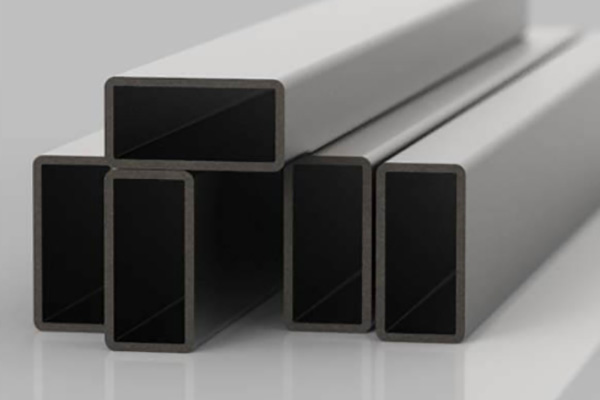

Rectangular Hollow Sections (RHS) are a popular choice in the construction, manufacturing, and engineering industries due to their unique combination of strength, versatility, and aesthetic appeal. These hollow steel sections, with their rectangular cross-sections, offer numerous advantages over other structural materials, making them a go-to option for a wide range of applications. In this article, we explore the key benefits of using Rectangular Hollow Sections and why they have become an integral part of modern construction and design.

Structural Strength and Stability

One of the most significant benefits of Rectangular Hollow Sections is their exceptional structural strength and stability. The closed shape of RHS provides high resistance to torsion, making them ideal for use in structures that require a high degree of rigidity. This makes RHS particularly well-suited for applications such as building frames, bridges, and cranes, where stability and load-bearing capacity are critical.

The geometric shape of RHS also allows for an even distribution of stress across the section, reducing the risk of bending or warping under heavy loads. This uniform stress distribution is especially important in applications where consistent performance is required, such as in the construction of columns, beams, and other load-bearing elements.

Versatility in Design and Application

Rectangular Hollow Sections offer remarkable versatility in both design and application. Their clean, linear appearance makes them a preferred choice for architects and designers who seek to create modern, aesthetically pleasing structures. RHS can be used in various configurations, whether as standalone structural elements or as part of a more complex assembly, offering flexibility in design without compromising strength.

In addition to their visual appeal, RHS can be easily fabricated, cut, welded, and drilled, allowing for a wide range of customization options. This adaptability makes them suitable for a variety of applications, from industrial machinery and equipment to residential and commercial building projects. The ability to tailor RHS to specific project requirements ensures that they can meet the diverse needs of different industries.

Efficient Use of Material

Another key advantage of Rectangular Hollow Sections is their efficient use of material. Unlike solid steel sections, RHS are hollow, which means they require less steel to produce while still maintaining high structural integrity. This not only reduces the overall weight of the structure but also lowers material costs, making RHS a cost-effective solution for construction and manufacturing projects.

The lightweight nature of RHS also translates to easier handling and transportation, reducing the logistical challenges associated with moving and installing heavy steel components. This can lead to significant savings in both time and labor, particularly in large-scale projects where efficiency is paramount.

Enhanced Durability and Corrosion Resistance

Rectangular Hollow Sections are known for their durability and resistance to environmental factors such as corrosion and wear. Many RHS are manufactured using high-quality steel that is treated with protective coatings, such as galvanization, to prevent rust and corrosion. This makes RHS an ideal choice for outdoor applications and structures exposed to harsh weather conditions or corrosive environments.

The durability of RHS also extends to their performance in seismic events. Their ability to absorb and dissipate energy makes them a reliable choice in earthquake-prone areas, where structural integrity can mean the difference between a building standing or collapsing during an earthquake.

Cost-Effective and Sustainable

The cost-effectiveness of Rectangular Hollow Sections goes beyond just material savings. Their ease of fabrication, installation, and reduced maintenance needs contribute to lower overall project costs. Additionally, the durability and long lifespan of RHS mean that they require less frequent replacement or repair, further reducing long-term expenses.

From a sustainability perspective, RHS is an environmentally friendly choice. The steel used in their production is often recyclable, contributing to the circular economy. The efficient use of materials also means that fewer raw materials are needed, minimizing the environmental impact of production.

Conclusion

Rectangular Hollow Sections offer a compelling combination of strength, versatility, efficiency, and durability, making them a favored choice across various industries. Whether used in construction, manufacturing, or design, RHS provides the structural integrity needed to create safe, reliable, and aesthetically pleasing structures while offering cost and environmental benefits. As industries continue to seek materials that balance performance with sustainability, Rectangular Hollow Sections are likely to remain a key player in modern engineering and construction.

Post time: Aug-21-2024