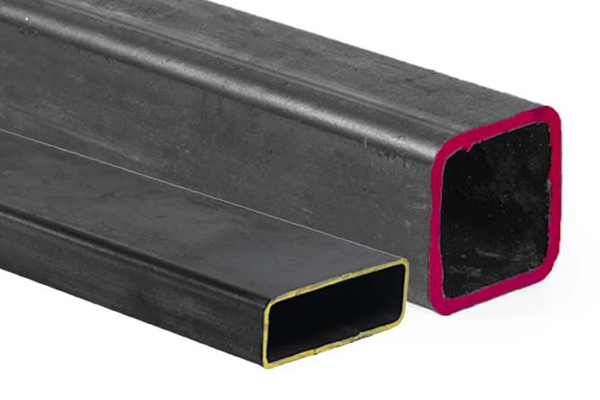

Demystifying Metal Tubes: Unveiling the Differences Between Square and Rectangular Tubes

Imagine venturing into the world of metal fabrication, where tubes reign supreme as versatile building blocks. But with an array of options available, differentiating between them can feel like deciphering a secret code. Today, we’ll tackle two common contenders: square tubes and rectangular tubes. While they might seem similar at first glance, understanding their key differences is crucial for selecting the right one for your project.

Unveiling the Shape: The Core Distinction

The fundamental difference lies in the cross-section of the tubes:

- Square tubes: These boast an entirely square cross-section, where all four sides are equal in length. Imagine a cube sliced in half lengthwise, and you have the visual representation of a square tube.

- Rectangular tubes: As the name suggests, they have a rectangular cross-section with four sides, but unlike square tubes, two sides are longer than the other two. Picture a shoebox without a top or bottom – that’s essentially a rectangular tube.

Beyond the Shape: Exploring Functionality and Applications

While shape is the defining factor, understanding the functional implications of each type is crucial:

- Strength and stability: Square tubes are generally considered more inherently stable due to their uniform distribution of material around the cross-section. This makes them ideal for applications requiring high torsional resistance, such as support columns, posts, and furniture frames.

- Bending and flexibility: Due to their rectangular shape, rectangular tubes offer greater flexibility in one direction (the direction of the longer sides). This can be advantageous for applications where bending along a specific axis is desired, such as creating curved handrails or framing structures requiring some level of flexibility.

- Material usage and weight: Square tubes, by virtue of their uniform sides, typically require less material to achieve the same cross-sectional area compared to rectangular tubes. This can translate to lighter weight for the same level of strength, making them a good choice for projects where weight optimization is a concern.

- Space constraints and aesthetics: The compact and uniform shape of square tubes makes them ideal for situations with limited space. Additionally, their clean lines and symmetrical design can contribute to a sleek and modern aesthetic. Rectangular tubes, on the other hand, can offer more design flexibility due to the variation in side lengths, allowing for customization to suit specific needs.

Choosing the Right Champion: Selecting the Perfect Tube for Your Project

Now that you’ve grasped the key differences, let’s explore how to choose the right tube for your project:

- Consider the primary function: If torsional resistance and overall stability are paramount, a square tube might be the better choice. However, if flexibility in one direction is required, a rectangular tube might be more suitable.

- Evaluate weight constraints: If weight optimization is crucial, a square tube might offer an advantage due to its material efficiency.

- Factor in space limitations: If working with limited space, the compact shape of a square tube might be beneficial.

- Don’t forget aesthetics: Consider how the tube’s shape will contribute to the overall design and choose the one that aligns best with your desired aesthetic.

Remember: When making your choice, it’s always recommended to consult with a qualified professional who can consider the specific needs of your project and guide you towards the optimal tube selection.

Post time: Feb-29-2024